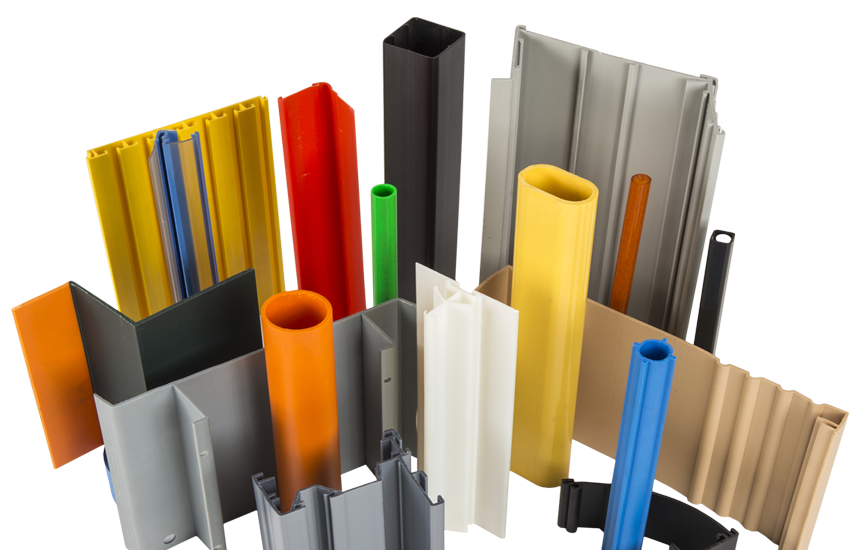

Some Of Custom Plastic Extrusions

Wiki Article

The Only Guide for Plastic Extrusion Profiles

Table of ContentsThe smart Trick of Custom Plastic Extrusion Manufacturers That Nobody is Talking AboutCustom Plastic Extrusion Manufacturers Things To Know Before You Get ThisThe smart Trick of Extruded Plastic Profiles That Nobody is DiscussingThe Plastic Extrusion Manufacturers Statements

Similar to any type of manufacturing procedure, the extruded profile will certainly differ somewhat during the process requiring tolerances on key measurements. Tolerances on plastic extrusions effect fit as well as function, and also the finest time to begin checking out tolerance needs is during the preliminary style stage. By functioning with Formtech early in the process, we can offer style for manufacturing help including tolerance demands.For a much more in-depth explanation concerning exactly how tolerances influence prices, and a general resistance guide, please click on this link. Bulk density is specified as the weight per system quantity of the plastics bought by Formtech for use in custom extrusion applications. Bulk thickness effects circulation and also feed rates on the extruder, and also variations in mass density of the plastic will certainly cause variants in size so it is an essential factor to consider for customized extrusion production operations We spoke about back pressure above, and also the importance of having the proper amount of back pressure throughout the extrusion procedure for physical residential property control (extruded plastic profiles).

As soon as the plastic substance exits the extrusion die in a compressed type, the substance will certainly relax, or expand somewhat. This is described as die swell. Pass away swell is product details, implying as an example a plastic (PVC) product will certainly experience a various die swell than a Polyethylene or Polypropylene substance.

In the extrusion process cleaning materials out of barrels, screws and plastic extrusion tooling takes some time as well as boosts price (https://filesharingtalk.com/members/572398-k3ll3rpl4st8?tab=aboutme&simple=1). If product changes are being made on the line from one task to the next, this can involve getting rid of and cleaning up the die, drawing the screw on the device to tidy, and brushing out the barrel of the maker while the screws are out.

Plastic Extrusion Manufacturers - Truths

The purging materials are so stable they can also be left in the extrusion pass away throughout storage space, put back on the extruder the next time the work requires to run, and also began without time consuming cleaning. The normal substance will certainly push the purge out of the die when it departures.

There are actually 2 methods that can be used to achieve this feeding process - https://www.twitch.tv/k3ll3rpl4st8/about. First, the material can be had in a hopper straight above the feed-throat of the extruder as well as fed by gravity. The screws will certainly then take in the optimum quantity of material they can with every transformation of the machine, as well as this is called flooding feeding.

The trips of the screw are not completely full of every change of the machine. This is called starve feeding of the extruder, as well as supplies some advantages to the extrusion service technician in particular situations. By not filling the screw channel totally, it provides even more control to the professional, and removes a few other variables that can accompany flooding feeding.

Top Guidelines Of Custom Plastic Extrusion Manufacturers

For every change of a solitary screw device, there is some slippage back over the trips of the screw. This slippage is useful for blending of materials and also colorants, however it creates a chance for some surging and also variation with the screw revolution. With this holding true, differing pressures as product comes off the screw can cause this handling issue for the extrusion professional.Call today or e-mail at [email shielded] for additional information.

Such a range of items as well as makes use of corresponds to the vast array of compatible products and also flexibility that the extrusion process manages in creating custom-made accounts to meet your exact specs. The plastic accounts developed in the extrusion process can be either flexible or stiff. Both deal benefits for various use cases (https://www.viki.com/users/k3ll3rpl4st8/about).

Custom Plastic Extrusions Fundamentals Explained

While it inevitably never succeeded at its designated objective, it nevertheless located routine usage in the automobile field in other ways, many thanks to its high liquid resistance and superb sealing efficiency. Automotive components typically made from Santoprene consist of weather seals, bumpers, cord jacketing, and also far more. Santoprene TPV's remarkable securing home additionally makes it especially helpful in building and construction, where it can be used to make window seals, tubes, electric adapters, and caster wheels (custom plastic extrusion manufacturers).We use advanced modern technology in order to develop the specific sort of extruded product you need. We are thrilled to start collaborating with you quickly!.

Production top quality products is as crucial to us as accomplishing the highest possible criteria for consumer solution. At the center of our solution are professional and dedicated employees who meet day-to-day obstacles with cutting-edge suggestions - custom plastic profiles. Client email Customized profiles/ shapes Twin Products Hollows Rods Tubes Angles Bindings Brackets Caps Stations Clips Edgings Insulators J-Retainers/ J-Clips Moldings Retainers Seals Sleeves Spacers Straps T-moldings Tapes Tracks Cold Temperature Performance Shade Matched Dual-Durometer Ease of Assembly Embossed Fire Resistant Flexible High Gloss High Temperature Performance Interlocking Locking Matte Non-Contact Food Quality Ribbed Break Fit Stiff Stamina Textured Weatherability Aerospace Device Air/Water/Pollution Control Automotive Structure Products Concrete Building Electrical Grass & Garden Logistics/ Transportation Marine Workplace Solutions Point of Acquisition (POP) Present Numerous Services Can Be Handled In-Line to Remove Additional Operations Adhesive/Transfer Tape Application Cut to Size Cutting Exploration Embossing Warm Sealing Laminating Punching Routing Slotting Unique Packaging Welding AIAG Automotive Sector Activity Group ASME American Culture of my link Mechanical Engineers ASTM American Culture for Testing and Products DOT Division of Transportation FDA Food and Medication Administration FMVSS Federal Electric Motor Car Safety Specifications MIL-STD Military Specs SAE Society of Automotive Engineers UL Underwriters Laboratories ISO International Company for Standardization.

Report this wiki page